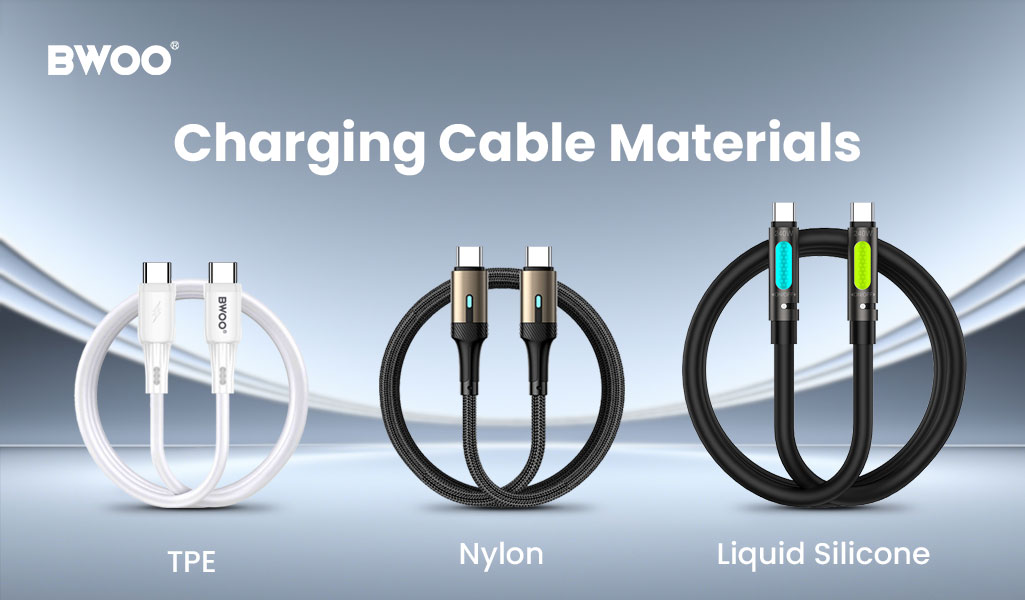

A Deep Analysis: Main Charging Cable Materials on the Market

2026-01-06 13:41

At first glance, most charging cables look perfectly fine.

Yet after months of daily use, many users encounter the same problem:

the cable jacket cracks at the connector (SR area), wires become exposed, and charging becomes unstable.

This failure is rarely accidental.

In reality, the surface material of a charging cable plays a decisive role in its durability, flexibility, and lifespan.

In this article, we take a deep, objective look at the three most common charging cable materials on the market today—TPE, nylon braided, and liquid silicone—explaining their real-world performance, structural weaknesses, and ideal use cases.

Material Breakdown: Which Cable Is Really Right for You?

1. TPE Cables: Soft, Familiar, but Fragile

Material Overview

TPE (Thermoplastic Elastomer) is the material used in many original charging cables from major smartphone brands.

It combines plastic and rubber properties and is widely adopted due to its cost efficiency.

Key Advantages

Very soft and flexible hand feel

Good elasticity in short-term use

Moderate manufacturing cost

Environmentally compliant and recyclable

Critical Weaknesses

Despite its popularity, TPE has a well-known limitation:

it degrades over time when exposed to skin oils, sweat, heat, and UV light.

Common aging symptoms include:

Yellowing of the outer jacket

Hardening and loss of elasticity

Micro-cracks near the SR (strain relief) area

Eventual brittle fracture and cable breakage

Best For

Users who prioritize softness and original-cable feel

Light usage scenarios with careful handling

Entry-level or price-sensitive markets

2. Nylon Braided Cables: Rugged and Long-Lasting

Material Overview

Nylon braided cables add a high-strength woven fiber layer around the internal cable jacket.

This external armor significantly improves mechanical protection.

Key Advantages

Excellent tensile strength and pull resistance

Strong anti-bending and anti-fraying performance

Reduced tangling in bags or pockets

Resistant to pet bites and accidental yanking

Among all mainstream materials, nylon braided cables are widely recognized as the hardest to physically break.

Trade-Offs

Stiffer hand feel compared to TPE or silicone

Lower-quality nylon may fray or fuzz over time

Less comfortable for bedside or portable use

Best For

Heavy users and frequent travelers

Consumers who throw cables into backpacks

Households with pets or children

High-volume e-commerce and retail markets

3. Liquid Silicone Cables: Soft Touch Meets High Durability

Material Overview

Liquid silicone cables use high-elasticity silicone rubber as the outer jacket, offering a very different tactile and mechanical profile compared to plastic-based materials.

Key Advantages

Extremely soft, skin-friendly texture (often compared to baby skin)

Outstanding rebound elasticity

Naturally resistant to oils, sweat, and temperature changes

After bending or coiling, the cable quickly returns to a straight shape

Why the Market Is Shifting

Liquid silicone effectively solves two major pain points:

The aging and cracking issues of TPE

The stiffness and rigidity of nylon braided cables

As a result, it has become a preferred material in the mid-to-high-end charging cable market, especially for premium devices and business users.

Best For

Users who value comfort and premium feel

Office, bedside, and daily carry scenarios

Brands targeting higher ASP and perceived quality

Beyond Materials: The Hidden Design Factors That Define Cable Lifespan

Strain Relief (SR) Design

The SR area—the short flexible section near the connector—is where most cable failures occur.

Even the best material can fail if:

The SR is too short

The hardness transition is poorly designed

The bending angle is not properly distributed

A well-engineered SR gradually disperses stress instead of concentrating it at one point.

Internal Structure: The Cable’s “Skeleton”

Inside every durable charging cable is a reinforced tensile core, often made from materials such as aramid fiber (commonly known as Kevlar).

This internal structure:

Absorbs pulling force

Protects the copper conductors

Maintains signal stability during repeated bending

For professional buyers, internal construction is just as important as the outer jacket material.

B2B Procurement Insights: Choosing the Right Material for Your Market

For Budget-Oriented Markets

Optimized reinforced TPE cables offer a practical balance between cost and acceptable durability when combined with improved SR design.

For E-commerce & Retail Channels

Nylon braided cables remain top sellers.

Their visual toughness directly reduces consumer doubts and contributes to lower return rates.

For Premium & Business Segments

Liquid silicone cables are increasingly preferred due to:

Superior tactile experience

Longer perceived lifespan

Stronger justification for higher pricing and margins

BWOO’s Commitment: Solving Cable Failure at the Material Level

At BWOO, cable durability is not determined by appearance alone.

Material Testing Lab

Each cable formulation undergoes 10,000+ bend and fatigue tests, simulating real-world daily use scenarios before mass production.

Full Material Customization

BWOO supports a complete range of solutions—from reinforced TPE and high-density nylon braiding to high-rebound liquid silicone—tailored to different market needs.

Design-Driven Quality

Every BWOO charging cable is engineered with a focus on material selection, internal structure, and SR optimization, not just surface aesthetics.

Conclusion:

Choosing the right charging cable material is not about trends—it is about long-term reliability.

In simple terms:

Want maximum durability? Choose nylon braided

Want premium feel and comfort? Choose liquid silicone

The right material can save users years of frustration—and help brands build lasting trust.

Related readings:

Does a Longer Charging Cable Mean Slower Speed?